Plastics have become an essential part of our society and reached all production sectors. Since the post-war period, plastics have contributed to the economic and social development of the Earth, addressing the greatest challenges in areas such as mobility, engineering and medicine. However, plastic pollution has become one of the most important critical global issues due to its impact on the ecosystem, wildlife and our health. Therefore, it is essential to implement a responsible approach to the life cycle of plastic products.

Plastics supply chain

The production and development of plastic products boomed impressively after the World War II, becoming part of our daily life.

Within the manufacturing sector, the plastics industry holds an irreplaceable and fundamental position in Italy and is a leader in Europe. However, the use of plastic materials has an impact on the environment and our health.

Virgin plastic is produced using raw materials such as oil, natural gas and fossil fuels, which cause CO2 emissions in the production stage.

Another problem is the disposal of plastic. Every year tons of plastic waste end up in the oceans and in landfills. Here they deteriorate, creating microplastics that threaten the wild flora, fauna and human beings.

Millions of animals, including those at risk of extinction, die every year by plastic because they get trapped inside plastic materials or starve to death because the ecosystem is altered. Microplastics coming from waste disposal have been found in plankton, which forms the basis of the oceanic food chain and consequently also our own.

VBN’s ecological commitment

It is therefore very important to adopt an environmentally friendly and increasingly sustainable approach to plastic production. Through the recovery and recycling of materials, the life cycle of raw materials can be extended and the amount of waste for disposal can be reduced. VBN produces profiles made of plastic materials and has been on the market for more than 60 years. The company is committed to the issue of environmental sustainability and aims to optimize energy consumption for a more responsible manufacturing through recycling of waste materials.

In fact, plastic waste can be reused and transformed into raw materials or secondary products, becoming new resources for product manufacturing.

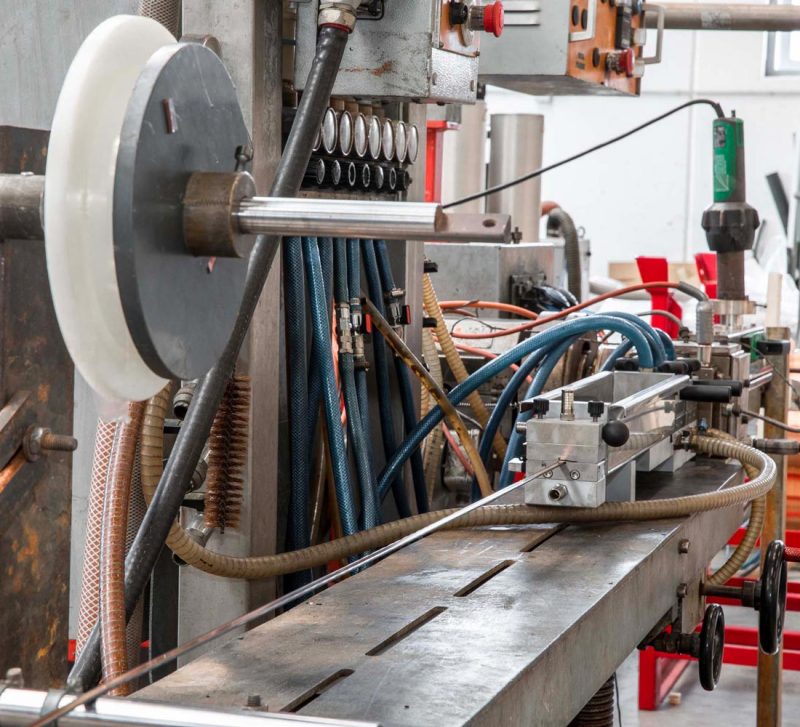

This step also involves the extrusion of plastic profiles, which are designed for recycling and being reused in respect of the environment.

Thanks to technologically advanced machinery and optimization of production processes, VBN can reduce CO2 emissions. In addition, the company takes advantage of a cogeneration and trigeneration plant to produce energy for internal consumption, which is used to power production, cooling and heating.