Plastic has changed the way we live with an extraordinary range of products and applications. However, in a linear economy plastic is largely discarded after use. It is believed that 80% of plastic products are abandoned without being reused. This system implies not only a huge loss of resources, but also a mismanagement of waste, which is the source of of many environmental problems.

The strategy to prevent waste of materials and damage to nature requires a paradigm shift, switching to a circular economy that aims to reuse plastic and preserve its value for as long as possible.

The plastics life cycle

The plastics life cycle can be divided into several stages: extraction of raw materials, production, use, disposal and recovery. The overproduction and overuse of plastic products have generated major impacts on terrestrial and marine ecosystems. Uncontrolled and disposable consumption has created a waste mountain. A large amount of plastic ends up in landfills or, even worse, in nature, polluting seas and threatening the life of aquatic organisms and birds. Plastic decomposition takes hundreds of years, causing long-term damage. During the degradation process, plastic can also fragment into microplastics. These very small particles can persist in the environment for even longer periods and lead to further alterations to ecosystems, ending up in the food chain of animals and even humans.

Recovery of plastics in the post-consumer stage

The aim of the circular economy is to intervene in the post-consumer stage, when plastic becomes waste. There are several strategies that can be employed to recycle plastics in order to reduce pollution and preserve resources.

Mechanical recycling involves the processing of plastic waste to create new products. After being sorted and washed, plastic is shredded into flakes or granules that are melted and reused to create items such as bottles, containers, profiles, pipes, and other goods. This process is suitable for recycling plastic materials such as PET and HDPE.

Chemical recycling can be used to process plastic waste into raw materials through chemical processes. This method degrades plastics into basic molecules, such as oils and monomers, which can be reused to produce new materials and resins. Chemical recycling holds promise for handling plastics that are not easily recycled through mechanical recycling, such as polystyrene (EPS) and some complex plastic blends.

Upcycling is a technique that allows to creatively transform plastic waste into products of higher value. For example, plastic bottles can be converted into furniture, bags or other design objects, extending the useful life of the material.

Closed-loop recycling is a manufacturing process that involves recycling plastic to create a new version of the same product. For example, plastic bottles can be recycled to create new plastic bottles. This system is the most efficient in terms of saving resources and reducing greenhouse gas emissions.

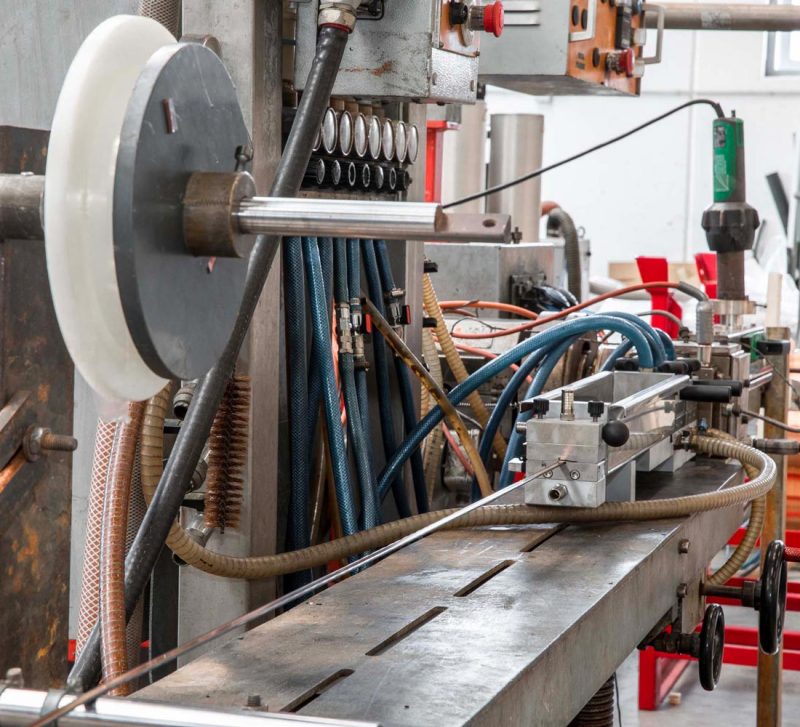

The use of recycled plastic in VBN’s extrusion processes

VBN designs and adopts extrusion processes increasingly aimed at enhancing the reuse of plastic materials to produce quality profiles while respecting the environment. The working cycles allow recycling to give plastics new uses in multiple fields and sectors. By employing a series of special extruders, which are specifically designed for plastic regeneration, it is possible to reuse both post-consumer waste and in-house industrial waste after cleaning, decontamination and filtering. Through the recovery of processing residues and special attention to packaging, VBN can further reduce their impact on the environment from the very beginning.