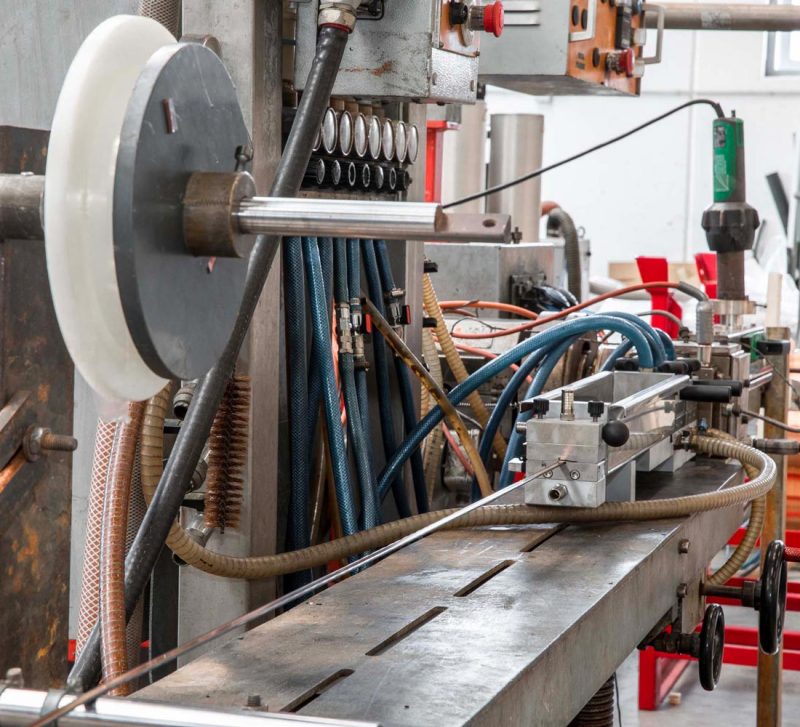

To ensure the highest quality, VBN has set up an in-house laboratory to carry out checks and tests. All design and processing stages are carefully monitored and subjected to performance tests. All checks take place several times during production employing the latest, most reliable measuring techniques.

Quality is under control

One of the main benefits of having an in-house quality laboratory is the opportunity to perform accurate and rigorous checks of each step of the production process, from the original idea to the final product.

VBN constantly checks the quality of the used raw material, analyzes the chemical and physical characteristics of plastic materials and verifies compliance with industry standards, with the aim of ensuring excellent and efficient processing.

Laboratory tests allow to identify deviations from required specifications or any possible defects before mass production begins.

Our in-house laboratory also allows to carry out in-depth studies on extrusion processes in order to improve performance and reduce production costs. Temperatures, extrusion speeds, material formulations and die modules configurations are also optimized.

Speed and customization of production

The use of our in-house laboratory allows for quick and timely results. Testing and analysis are carried out first-hand, without resorting to external analysis laboratories. This allows to speed up the design time and reduce production and product delivery times. VBN is able to respond promptly to any problems, quickly analyze defective samples, identify causes and find solutions in shorter time.

It is also possible to produce tailored plastic profiles and tubes, defining and checking every detail of the design, product and extrusion process performance features together with the customer. The in-house laboratory ensures the flexibility to quickly adapt to the customer’s needs and customization requests. It is possible to test and produce prototypes quickly, making changes and improvements based on feedback.

Constant improvement, inspection and certifications

Thanks to the laboratory, engineers constantly collect data and feedback regarding product and material performance. VBN operates with a perspective of continuous improvement. It is essential to be able to experiment with new formulas, test new technologies and evaluate the effectiveness of different solutions. This approach allows us to stay ahead in the industry and to offer innovative products that stand out from the competition and meet at best market and customer needs.

Our in-house quality laboratory also helps obtaining and maintaining internationally recognized quality certifications. These certifications, such as ISO 9001, demonstrate VBN’s commitment to the highest quality standards and the pursuit of maximum customer satisfaction.

Learn more about our in-house laboratory.