Thermoplastic flat profiles are used in many fields: from lighting to window and door frames, from guards to construction, and even in tennis court tiles. Their great versatility is not the only quality of these products, which are produced through the plastic extrusion process. The use of flat profiles has many benefits.

Easy processing and flexibility of thermoplastic profiles

Unlike thermoset polymers, thermoplastic polymers can be melted and handled multiple times without losing their mechanical properties. The capability to be easily molded, cut and assembled makes them a perfect material for applications requiring reliability and durability. The extrusion process allows thermoplastic flat profiles with consistent cross sections to be produced continuously and with fast cycle times. Extrusion technology allows to produce profiles with very precise dimensional tolerances, ensuring the consistent quality of the final product.

In addition to standard models, customized solutions can be manufactured by designing custom dies. Once the die for extrusion has been designed and created, the various processing steps are carried out in series. This approach allows to produce flat thermoplastic profiles in large quantities, significantly reducing production time and costs. The wide range of colors, finishes and textures makes it possible to obtain products with an excellent aesthetic result to meet the specific needs of each project.

The mechanical and thermal resistance of thermoplastic flat profiles

Flat thermoplastic profiles are lightweight and durable, capable to withstand significant mechanical loads without deforming or yielding. This strength is particularly valued in applications where structural stability and durability is required, such as in construction, plant engineering, and furniture. The choice of materials is critical in making thermoplastic flat profiles capable of maintaining functionality and integrity according to the context of use, responding to the specific needs.

The use of profiles in outdoor spaces represents an additional challenge because of adverse weather conditions. In fact, excessive heat can damage their shape, while low temperatures can weaken the structure and cause breakage.

The electrical and thermal insulation capacity of flat profiles

The excellent electrical and thermal insulation properties of thermoplastic flat profiles make these products particularly suitable for being used as covers for light sources or for applications in the plant sector. The plastic they are made of can regulate the external temperature of ceiling lights and prevent any power leakage in electrical panels. These features allow thermoplastic flat profiles to be placed in potentially hazardous contexts, where protection from thermal and electrical agents is crucial.

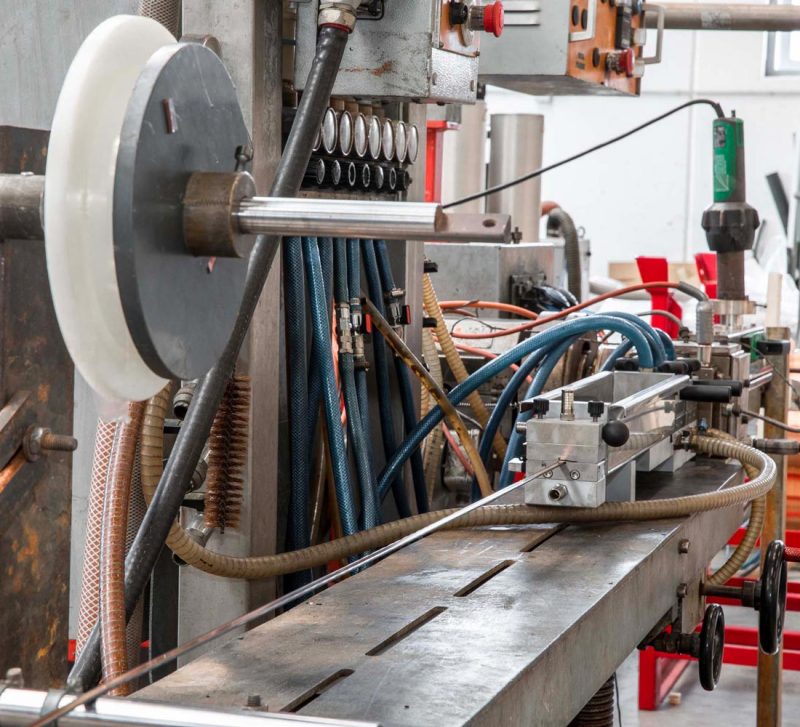

VBN’s thermoplastic profiles

With over 65 years of experience in plastics extrusion, VBN can design and extrude thermoplastic flat profiles that are suitable for a wide variety of requirements. Products are customized according to requirements and completed with finishing processes such as cutting, drilling, milling or blanking. The design is custom-made in cooperation with a team of experts who follow all stages of project development, from the original idea to mass production. In addition, VBN’s thermoplastic profiles comply with the international DIN 16941 “Thermoplastics extruded profiles” standard. Inspection, testing and optimized production processes ensure the quality of the final product.