VBN introduced an innovative storage system with earthquake-resistant cantilever racks and multi-directional forklifts, transforming a warehouse into a high logistics efficiency system. Optimizing space for item storage is an essential requirement for improving operational efficiency and providing better service to customers in organizing deliveries.

Optimized storage capacity with the new racking system

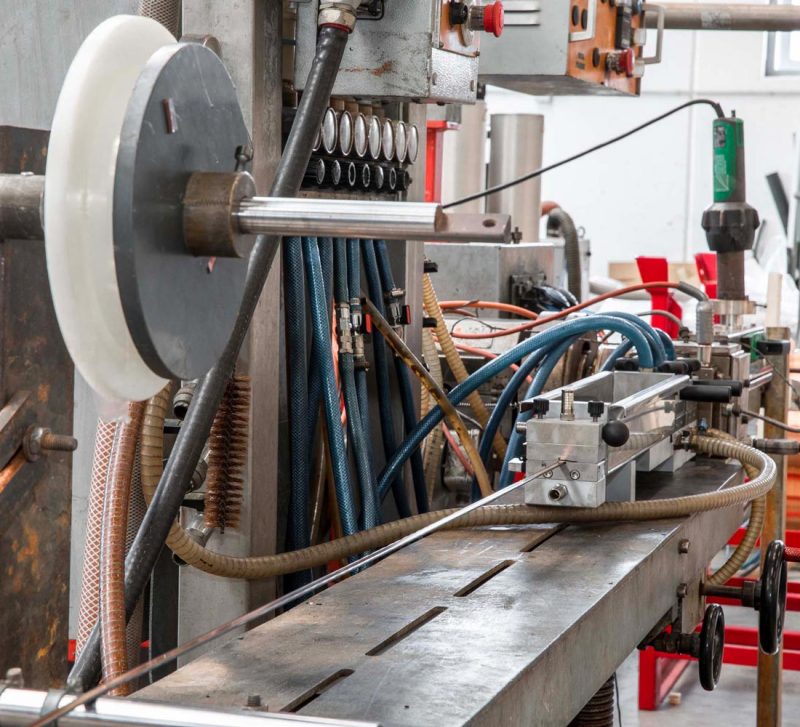

The implementation of new earthquake-resistant cantilever racks and multi-directional forklifts marked a turning point in VBN’s corporate logistics. The project was carried out by Soluzione Intralogistica, which proved to be a valuable partner in the development of technologically advanced solutions for warehouse handling, professionally taking care of all design and development phases.

The new facility has allowed us to build an extremely efficient 600-square-meter storage area distributed over 7 height loading levels. 560 4-meter metal containers can be used in the warehouse. This significant increase in storage capacity has a direct impact on the logistics strategy, representing a significant step forward in the management operations of plastic materials and the final extruded products. This flexible installation makes cantilever racking a very functional solution for handling long and bulky loads, such as pipes and extruded profiles.

Technologies that improve operational efficiency

Inside the warehouse, loads are moved by a multi-directional forklift, the star of this technological evolution. It moves with ease through 5 1,800mm transfer aisles. Taking full advantage of the available space, it ensures fast and efficient material handling. The precision of this smooth process brings tangible value to the entire logistics chain, improving productivity.

In addition, thanks to location mapping, the tracking of goods becomes more efficient. This solution allows to excellently manage stock, reduce handling times, and speed up deposit and withdrawal operations.

VBN: innovation always serving customers

Soluzione Intralogistica allowed us to build a performing facility to meet VBN’s specific storage and handling needs.

This investment becomes a benefit for customers. With an optimized racking system we can keep a larger and more varied inventory, improving product availability in the warehouse. The possibility of storing materials of different sizes and shapes also allows us to effectively meet more specific, customized requests.

A well-organized stocking system also reduces the risk of order errors, increasing customer satisfaction. Greater efficiency in the warehouse results in shorter preparation and shipping times, ensuring faster deliveries.