In the field of refrigeration, more and more high-performance materials are required: the machines, in fact, must be able to guarantee ever greater energy efficiency. For this reason, the new models of plastic profiles for refrigeration become indispensable.

The study and research of particular sections, and the use of materials with high insulating power, give the final profile an undoubted competitive advantage.

The refrigeration application sector has been the core business of VBN SpA, since its foundation; we take care of extruding thermal insulating profiles that are applied to large refrigerated systems and to machinery such as cold rooms, professional and domestic refrigerator furniture, refrigerated cabinets and counters.

Advantages of plastic profiles for refrigeration

Using plastic profiles in the domestic and professional refrigeration sector has numerous advantages, such as:

⦁ Creation of customized profiles

⦁ Easy assembly

⦁ Reduction of condensation and low thermal conductivity

⦁ Increased energy efficiency

⦁ Easy cleaning and resistance to common detergents

⦁ Hermetic seal.

VBN, plastic profiles for refrigeration

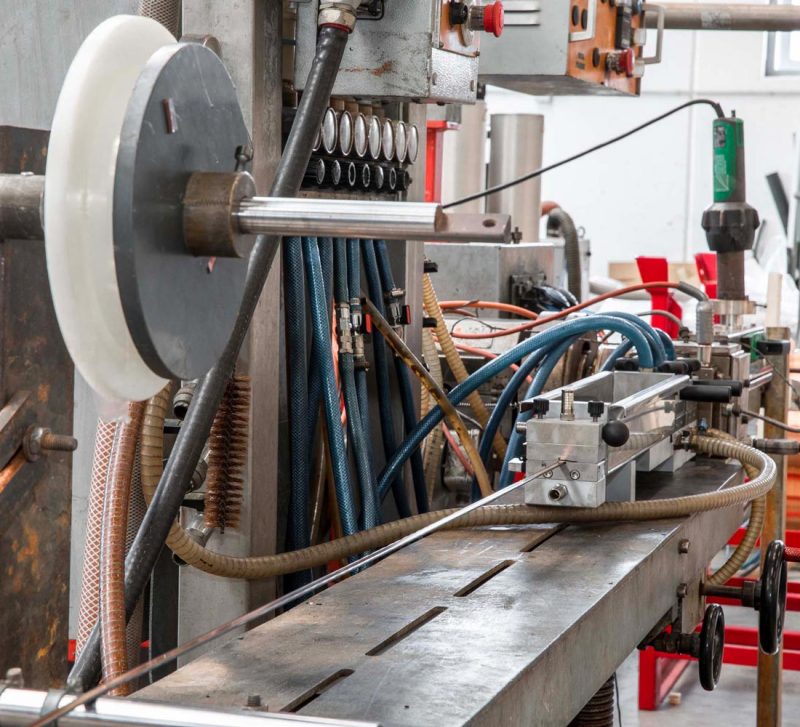

Today, VBN spa provides a 360 ° service from the initial study of the profile to customized processing and services for the customer. Our company has a production capacity of over 4,000 tons of profiles per year thanks to the use of more than 50 extruders.

For refrigerated systems, we make

⦁ Gripper profiles or sheet metal junction

⦁ Panel joining profiles

⦁ sanitary corner profiles

⦁ floor profiles

⦁ cell base profiles

For refrigerated cabinets, we produce:

⦁ Door profiles and gasket door profiles

⦁ Handle profiles

⦁ Glass door profiles

For refrigerated tables, we produce:

⦁ Handle profiles

⦁ Body profiles

⦁ Thermal bridge profiles

⦁ Door profiles and gasket door profiles

⦁ Glass door profiles

For refrigerated counters and metal shelving, we produce:

⦁ Label / price holder profiles

⦁ Bumper profiles

⦁ Adjustable plinth profiles