Plastic is too valuable to be wasted in the environment: it deserves a second life. Ecological profiles can turn plastic waste into a resource for making new products. By reusing plastics, it is possible to reduce environmental impact and promote a more ecosystem-friendly development model in line with the principles of circular economy.

Circular economy and reduction of the ecological footprint

Ecological profiles, which are made from regenerated plastic materials, are a practical example of circular economy. They represent a production model that is based on the reuse of resources to reduce waste and minimize environmental impact. The use of recycled plastics in the manufacturing of these products can give new life to materials that are otherwise destined for disposal in landfills or to be abandoned in the environment, becoming a pollution source. Their recovery also involves a lower use of virgin raw materials, leading to a reduction in CO2 emissions and energy consumption. Each ecological profile contributes to the preservation of natural resources, protecting ecosystems for future generations.

Ecological profiles

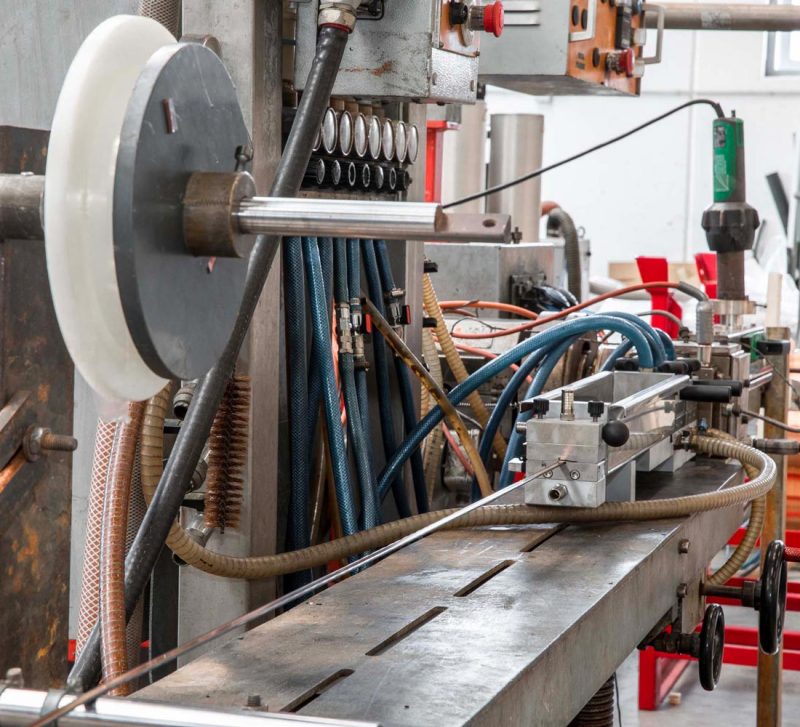

Plastic recycling and the extrusion process represent two key steps of a production system oriented toward sustainability and efficiency, perfectly in line with the circular economy model, where waste becomes a resource. Through a continuous cycle of recovery, regeneration and re-entry into the market, waste is reduced and this contributes to the health of the planet. Post-consumer plastics, which are the basis of ecological profiles, are recovered from various sources, treated and processed to create new polymers that are ready to be used in many industrial applications.

VBN’s commitment to environmental sustainability

VBN stands out for their commitment to environmental sustainability. VBN invests in the research and development of cutting-edge solutions, such as environmentally friendly profiles made from recycled plastic, which respect nature and promote responsible resource management. This product line is made from high-quality recycled materials, which do not compromise performance in terms of strength and durability. All ecological profiles produced by VBN are the result of an innovative and responsible approach that aims to combine functional and aesthetic requirements while deeply respecting the environment. The working cycles allow post-consumer plastics to be reused and used again in multiple application fields and production sectors. Moreover, the extrusion process is optimized to minimize waste and emissions, offering solutions that meet the needs of an increasingly ecologically conscious market.

Learn more about VBN’s commitment for recycled plastics processing