QUALITY

Testing and inspections

Inspections and testing are an integral part of our production philosophy geared toward the highest quality and certified by ISO 9001.

Operational planning establishes controls and testing appropriate to each individual project.

Quality control is conducted through the use of modern technologies that best support the experience and professionalism of the technicians.

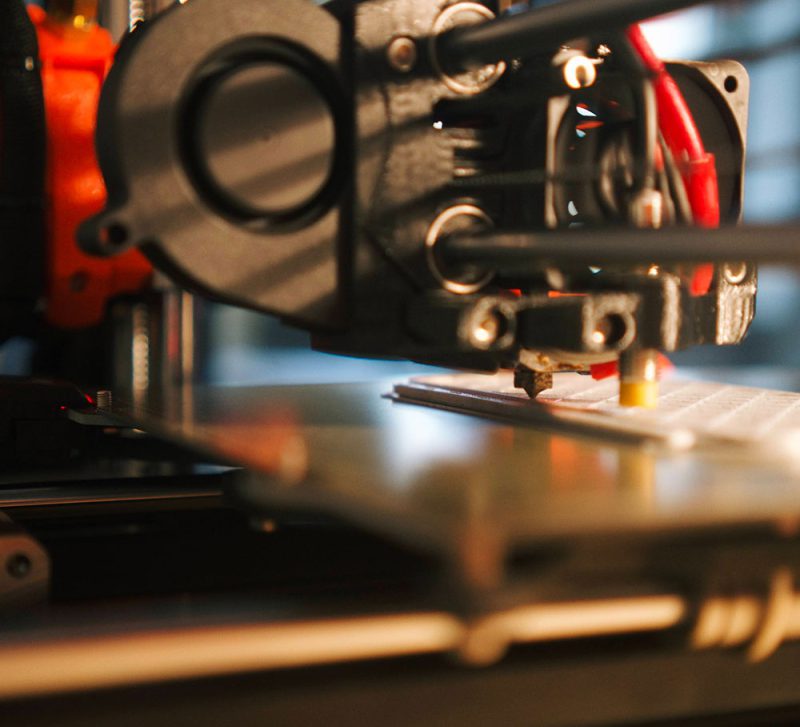

At the beginning of each individual production batch, we ensure the correct set up of the machinery for profile extrusion. We perform a preliminary check to start up the equipment and fine-tune the die. The inspection step is repeated several times during production, using the latest measurement techniques. In addition, during the production process, the profile is tested and proven to ascertain full compliance with the required standards. Quality improvement in production processes and continuous updating on extrusion techniques enable us to evolve and bring standards forward, aiming for excellence.